Description

Clamp-on ultrasonic flowmeters represent a non-invasive solution for accurately measuring fluid flow across various industries. Their distinct advantage lies in eliminating the need for cutting pipes during installation, resulting in significantly reduced installation and commissioning costs compared to other flow measurement methods. These flowmeters boast high accuracy, making them suitable as reference sensors for precise flow measurement.

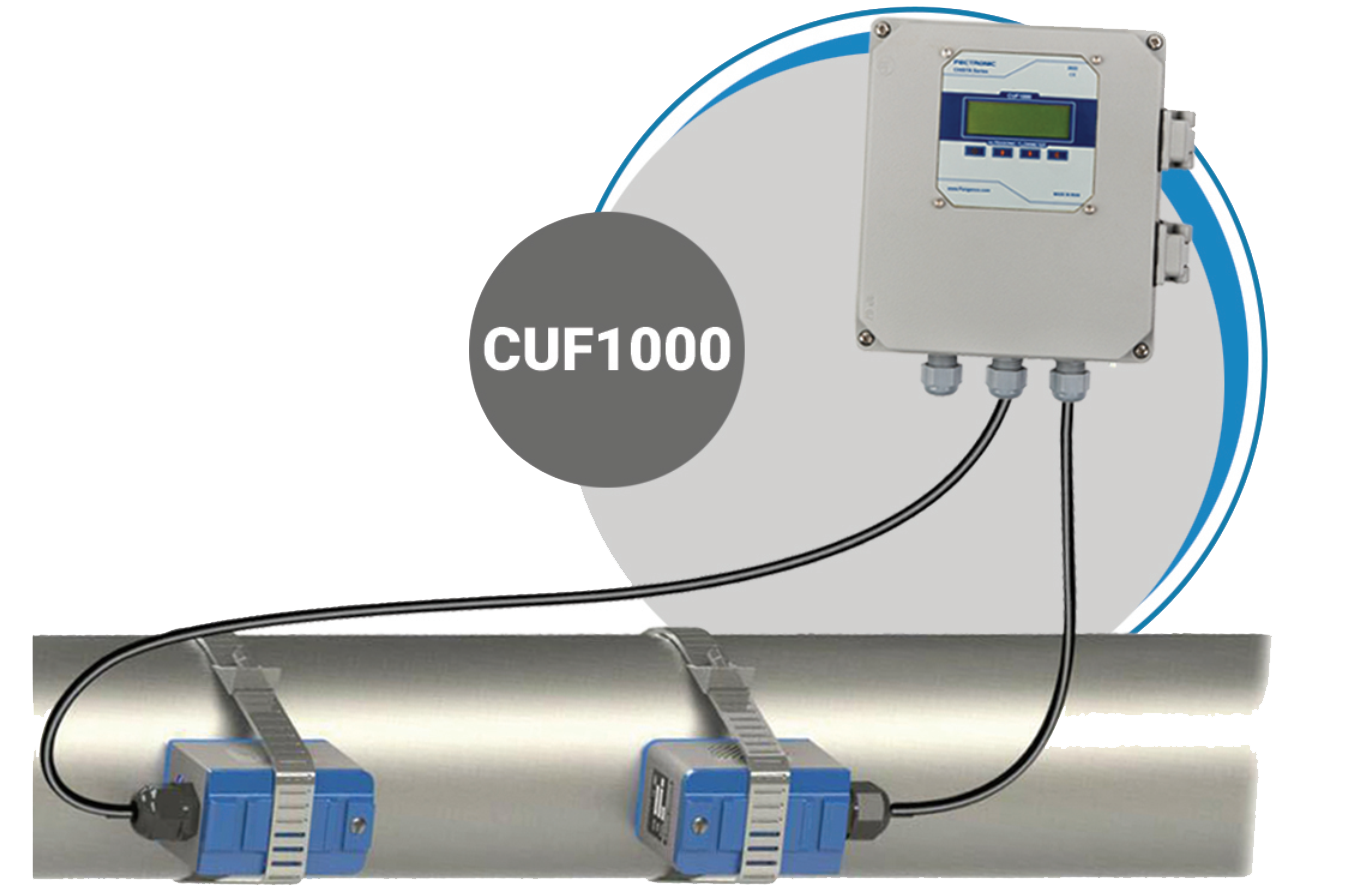

Furthermore, the seamless installation and commissioning process of these flowmeters enables users to verify the performance of other equipment integrated into the operational process. The flowmeter system comprises two sensor components and one transmitter component. In this flowmeter type, the sensor components employ ultrasonic wave transmission and reception, while the transmitter processes the transmitted and received signals, utilizing the principles of time transition and fluid velocity to ultimately measure the flow rate passing through the pipe.

Within this flowmeter, two sensors operate in opposite directions inside the pipe’s environment. Each sensor simultaneously receives and transmits ultrasonic signals, concurrently measuring signal transmission. As the fluid flows through the pipe, signals experience acceleration in the direction of flow and delay in the opposite direction. The time differential measured by the sensors directly correlates to the flow rate, constituting the fundamental working principle of ultrasonic flowmeters.

Clamp-on ultrasonic flowmeters cater to a wide array of flow measurement applications, making them applicable in municipal sectors for water management, wastewater treatment, potable water supply, energy production, and condensate processing. Additionally, these flowmeters find use in processing industries like oil and gas, chemicals, food and beverage, and pharmaceuticals.

Their versatile capabilities extend to fluid temperature measurement, with minimal interference from factors such as pressure, fluid movement, and sedimentation in the tank. Moreover, steam and mist factors, dielectric coefficient, foam, fluid corrosiveness, tank material, and sediment in the measuring tube do not impact the accuracy of measurements.

For applications involving measuring bubble rates or impurities, these flowmeters perform exceptionally well, with optimal accuracy achieved within a maximum range of 2%. Beyond flow measurement, they also serve as valuable devices for verifying the performance of other installed equipment, showcasing their reliability and flexibility.

As a portable solution, these flowmeters offer ease of use and adaptability without requiring pipe cutting, allowing for effortless relocation as needed.

• Fluid temperature measurement

• Factors of pressure, fluid movement, sedimentation in the tank have very little effect on the measurement process

• Steam and mist factors, dielectric coefficient, foam, fluid corrosiveness, tank material, sediment in the measuring tube, impact to the measuring tube are ineffective in the measurement process.

• The best condition for measuring the bubble rate or impurity is maximum 2%

• Functionality as a device for verifying other installed devices

• No need to cut the pipeline

• Portable and portable

Reviews

There are no reviews yet.